A Subsidiary of Meghna Group

A Subsidiary of Meghna Group

ABOUT US

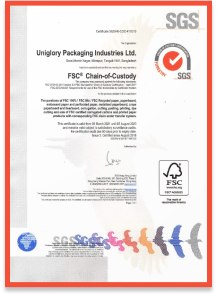

Uniglory Ltd., a subsidiary of Meghna Group, is an eminent provider of 100% export oriented top-tier packaging services to the international apparel retailers. The state of the art facility at Uniglory coupled with a team of highly skilled professionals, empower us to consistently deliver on time quality products’ on a day to day basis.

In line with our steadfast commitment to cater to the diverse client requirements, we offer both standardized and customized packaging solutions. Embracing our environmentally conscious ethos, we prioritize the utilization of sustainable materials and methodologies throughout our operations. Uniglory has earned recognition for its persistent dedication to quality, innovation, and sustainability, and we remain determined in our pursuit of delivering exceptional products and services to our esteemed clientele.

Name of the Concerns:

● Uniglory Paper & Packaging (UPPL)

● Uniglory Paper Industries Ltd. (UPIL)

● Transworld Packaging Ltd. (TWPL)

● Shore To Shore Brand Packaging Ltd. (Technical JV with UPIL)

Year of Establishment

2010

Corporate Office

Forum-Meghna Tower (level 22)

187-188B, Gulshan-Tejgaon Link Road

Tejgaon I/A, Dhaka-1208

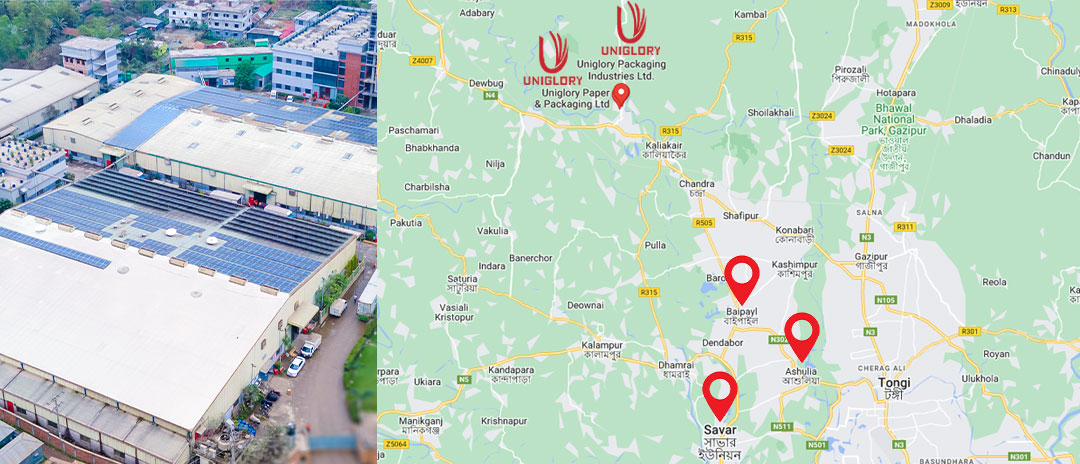

Factory

Gorai, Momin Nagar, Mirzapur,

Tangail – 1941

Vill: Bormi, PO: Bormi Bazar, PS: Sreepur, Gazipur 1743

Factory Area

16 acres

VISION

MISSION

- On time defect free products at a competitive price.

- Innovative products of eco-sustainable & recycled materials using maximum possible renewable energy to reduce carbon footprint.

ADVANTAGES & STRENGTHS

-

Strategic location: The production facilities are strategically located near major RMG factory clusters, enabling fast & timely delivery than that of the competitions. Being located outside EPZ also adds to its quick delivery support.

-

Specialization: The company specializes in RMG accessories manufacturing, which means it does not compete with the big players in the RMG sector. Instead, it can partner with them to provide support with trims, buttons, hangers, poly bags, cartons, and other accessories.

-

Sufficient capacity: The company has sufficient capacity with automated machines and equipment to meet the growing demands of all international brands.

-

Door-to-door delivery services: We adopt door-to-door delivery services for direct and expedited shipment of our products to clients.

-

Number of warehouses: The company has a number of warehouses that enable it to keep enough paper stocks to meet the additional demand.

-

Future expansion: The company has plans for future expansion that will enable it to support the growing customer demands.

-

Financial Strength: The company has a strong financial position and can streamline funds efficiently to different facets of its business. It also continuously seeks ways to reduce costs (such as using steam from the flue gas of the gas generator) to share savings with its customers.

-

Efficient Transport: The company has its own fleet of covered vans (80 plus covered vans) and has strategically located its factories close to each other. This ensures efficient transportation of its products from production to delivery.

-

Captive Gas Generator: Having in-house captive gas generator ensures uninterrupted supply of power for production.

-

Solar Power Generation System: As of now 800 KWh of solar power is set in the factory facilities ensuring a significant percentage (50% +) of the day's operations through clean solar power.

-

Keeping Raw Materials for 3-6 months: Our company keeps a 3 to 6 month inventory of raw materials depending on the lead time to ensure a steady supply, capitalize on advantageous pricing, and prepare for potential supply chain disruptions, thereby mitigating the risk of production delays or stockouts.